laser level

How to Use a Laser Level Indoor and Outdoor?

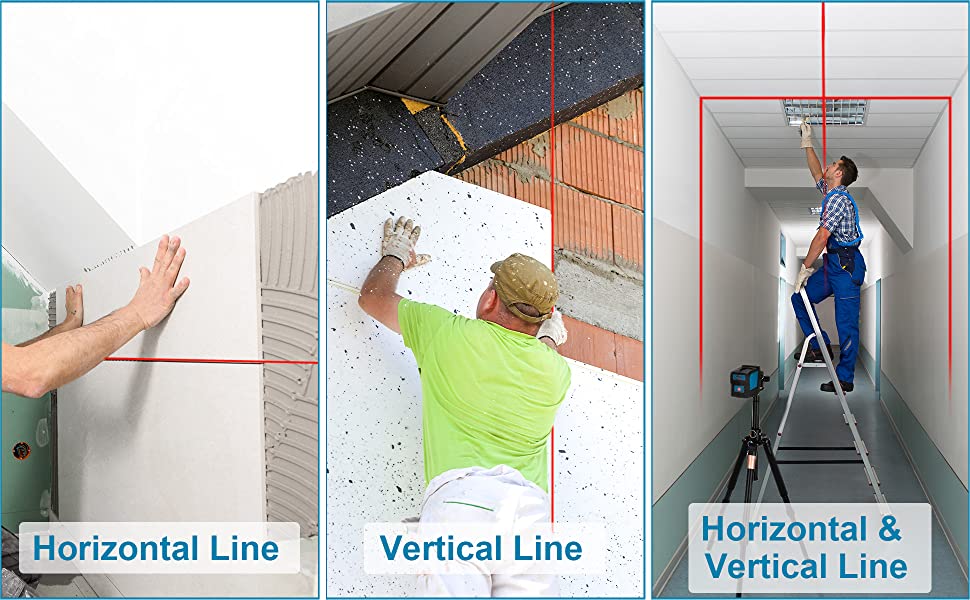

The laser level is a standard calibration tool. It measures the angle of inclination relative to the horizontal position, the flatness, and straightness of machine tool-type equipment guides, and the horizontal and vertical position of equipment installations. Before understanding the use of the laser level, it is necessary to know some basic knowledge about it.

The use of laser levelers

- Sheet metal working and ascribing and positioning of steel plates in mechanical engineering

- As auxiliary and positioning marks in various industrial production facilities

- Positioning in the equipment installation and construction industry

The five functions of laser level meter

- Laser levels can be used to measure the levelness of flat surfaces or for hanging pictures etc.

- The output laser vertical surface and horizontal point.

- The laser leveler has a leveling bead on it, which can measure whether the level surface is level or not.

- The laser leveler has led beads on it; even at night, you can see the leveling beads.

- The laser level can be added with magnets for a more practical and convenient adsorption function.

How to choose a laser level?

Manual or self-levelling

Laser levels are usually available in manual and automatic versions. Manual laser levels require the user to align the bubbles in their vial. Automatic or self-leveling laser levels use internal pendulums, magnets, and gravity to level. These laser levels are used for tasks that require the highest level of accuracy.

It is recommended that you consider purchasing a ‘self-leveling’ laser level. These models are the easiest to use and offer the highest level of accuracy. They are ideal for a variety of leveling and plumbing tasks.

How to choose a laser level for outdoor use?

You can choose a rotating laser level for outdoor use as it can project a 360-degree plane horizontally, vertically, or simultaneously, making it ideal for outdoor use.

Choosing a red or green laser level?

If you are working indoors, there is no significant difference between the two, but if you are working outdoors, the green light of a green laser level is clearer than red light and has a more comprehensive measuring range.

The rugged over-molded housing and IP54 rated housing cover provide a waterproof and dustproof cover for the laser level, making it the perfect choice for long, hard days on-the-job site.

How do I use a laser level?

Adjusting the instrument

- Place the instrument on the reference plane or stand.

- Turn on the laser level.

- If the laser blinks and alarms, adjust the instrument’s position or fine-tune the stand to level the instrument.

- Adjust the height of the instrument by shaking the handle or lifting the stand.

- If the laser line is dark or bright, check the light outlet; if there is dirt, wipe it clean with a cotton swab dipped in alcohol.

Operation method

- Turn the switch to the ON position, i.e., release the locking condition, turn on the power, and then the horizontal and vertical laser lines will be lit and projected on the target.

- Rotate the instrument horizontally so that the vertical laser line falls in the desired position.

- After the operation, you need to turn off the power and turn the knob switch to the OFF position. Otherwise, it will affect the accuracy.

Caution

- When the instrument needs to be transported over long distances or when moving into the packing box, the switch knob should be turned off.

- When there is a flashing laser, and a beeping sound during the instrument’s moving, the switch knob is turned to the OFF position. At this time, please turn the switch knob to the OFF position to avoid damaging the instrument.

- If you use the laser level outdoors, you need a laser detector to find the light beam.

Safety precautions to use

- Do not look directly at the laser beam to avoid damage to the eyes.

- The laser marker output is located at the output hole.

- Do not dismantle the instrument for internal maintenance; repairs can only be carried out through authorized repair centers.

- The instrument should comply with the laser radiation safety level standard.

- When the laser level is not used for an extended period, the batteries inside the machine should be taken out. Store the machine properly in a soft case or a box in a dry and ventilated place.

Conclusion

The above is the role of the laser level meter and the use of the method of introduction, but also need to pay attention to is in the operation of the whole process to take lightly. During the laser line projector, it may be necessary to wear goggles to prevent the possibility of laser damage to the eyes. Prolonged exposure of the human eye to laser light can cause damage to the human eye.